Wednesday, 20 November 2013

Saturday, 16 November 2013

Sunday, 2 June 2013

Thursday, 30 May 2013

Tuesday, 21 May 2013

Final Design: Rethink about use of material

Thursday, 16 May 2013

Workshop Experimentation: Building process and issues within

During the building process I noticed that the weight would be over the limit by 500grms. I am still investigating about how to reduce the weight of the stool by keeping its overall shape

Saturday, 4 May 2013

Sunday, 21 April 2013

Tuesday, 16 April 2013

Tuesday, 9 April 2013

Monday, 8 April 2013

Sunday, 31 March 2013

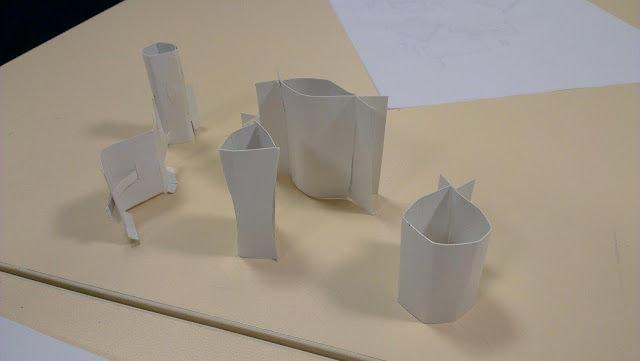

Research: Material Testing B

The material i tested was foam, pvc pipe, bending wire, acrylic and polyprop. Using the foam as the seat makes the user feel more comfortable and it also hides the construction part of the stool. The bad thing about foam is that it tends to wear with time. The pvc piping can be used for the structural part of th

e stool, but i might get warped or broke if heavy weight is applied on it. Bending wire is a way for providing an original way for a seat, but with time, the metal tends to oxydide and makes the seat dirty. Acrylic sheet is also a way to provide structural strength, because its not that flexible easy to work with. It is also weatherproof, the bad side is that it tends to get heavy.

Tuesday, 19 March 2013

Thursday, 14 March 2013

Monday, 11 March 2013

Subscribe to:

Comments (Atom)